The achievements of raw material processing technology in agriculture are largely dependent on usage of biotechnological methods of processing, usage of high-tech methods with the purpose of long-term storage, the preparative separation of chemical components of raw materials, manufacture of food additives based on reprocessing of agricultural products.

Modern technologies of agricultural raw material processing cause changes in gas-liquid substances in a wide range of humidity, temperature and pressure. Gas-liquid technologies effectively influence raw materials which achieve new quality characteristics and can be divided into separate classes of chemical compounds.

The main aim of this article is to analyze the technological features of gas-liquid processing of agricultural raw materials for manufacture of highly concentrated, biologically active substances. The achievement of this aim allows to determine the optimum operating parameters of CO2-extraction for equipment of different productivity, insures the high quality of the extract achieved at the level of laboratory researches and reduce the process of extracting of valuable substances from vegetative raw materials [1-3].

The extraction processes are significant and they depend on carbon dioxide under sub- and supercritical conditions. The authors participated in preliminary theoretical and experimental investigations which allowed to formulate the basic principals of gas-liquid processing of raw materials [4-6]. The large-scale transfer of experimental results to industrial conditions is a serious scientific and applied task.

Despite the large number of publications and object of intellectual property in the field of gas-liquid technologies, currently there are no clear algorithms of industrial development of sub- and supercritical CO2-extraction processes taking into account the mass transfer in the layer of material with the specified quality of CO2-extract [7-9]. The quality of CO2-extracts is primarily determined by the presence of target component in them such as azulene in chamomile, squalene in amaranth, carvone in cumin, cineol in bay leaf. This condition is achieved by selectivity of liquid and compressed carbon dioxide as a solvent or the usage of azeotropic mixture and co-solvents in extraction system.

The industrial realization of sub- and supercritical CO2-extraction technology of valuable components from raw materials involves scaling of data obtained in the industrial volumes [10-12].

The subcritical CO2-extraction is used at temperatures ranging from +5 to +28 °C and saturated vapor pressure of CO2 from 3.8 to 7.2 MPa. Methods of systematic analysis allowed to develop the conception of new scientific area (CO2-technologies) in food industry for processing of food raw materials of different origin.

The regularities of interaction, functioning and development of technological processes based on interaction of food with carbon dioxide at stable or changable phase states have been identified. They allowed to develop the scientific basis of engineering solutions in the field of the of CO2-processing technology of food raw materials.

The research of scientific bases for the selective extraction and flow-jet processing allowed to identified crystallization mechanisms in the complex system “CO2-component” and conditions for the effect of “co-extraction” at interaction of vegetative raw materials with CO2-solvent were defined.

The basic patterns of activation of proteolytic processes of muscle tissues under the influence of carbon dioxide gas at the pressure up to 4.0 MPa were identified.

The main results of the first stage of investigation are the next:

- combined methods of analysis of the thermodynamic efficiency of the direct flowing crystallization and the selective extraction in the system “Energy-Economy-Ecology” were identified;

- the methodology of the selection and the sequence of design development for evaluation of the regime and technological characteristics of the original equipment for CO2-technologies were developed;

- the generalized approaches to the processes which revealed interactive factors of new technological processes, the formulation of scientific areas and generalized solutions for many challenges which arise in food and cosmetic industrial enterprises were developed;

- the ability of the extraction efficiency control of target substances from vegetative raw materials with the help of directional crushing of the cellular structure of raw materials was proved;

- the way of homogenization of vegetative raw materials by the consistent processing pressure change was substantiated. The regularities of purification of grape juice and wine tartrates with the purpose of stabilizing the quality and customer value of finished products were identified;

- the hydroaerosols formation conditions, fine granulated water ice, “dry snow” (from CO2 and water ice ) in gasdynamic jet devices were identified. The usage of supercritical carbon dioxide as a technological agent is a new scientific area in food technology which is actively developed at the present time.

CO2 significantly alters its properties under supercritical condition and it can be used not only as an effective extractant but also for regeneration of polymeric adsorbents.

Supercritical extraction technologies are characterized by high diffusion potential of fluid with high selectivity of extraction and the higher yield of extracted components without any traces of solvent in finished product. The easiness of extractant regeneration and in many cases the single-stage condition of operation define low energy consumption of the process.

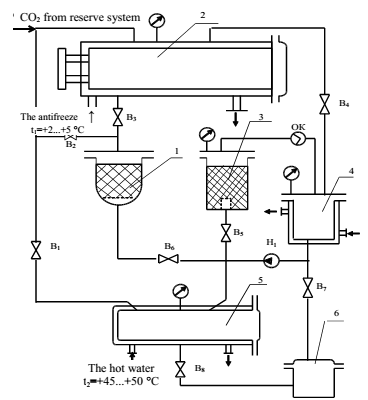

A hardware-technological scheme of CO2-extract manufacture implemented in the extraction plant “Caravan Company” (Krasnodar) is shown in figure 1. This company is the leading organization of the Interregional Scientific and Production Center “Extract Product”.

The distinctive feature of the scheme developed by the authors is the usage of ultrasonic method of intensification of the extraction process. The combinated scheme of CO2-extraction at sub- and supercritical conditions is of considerable interest.

Figure 1. Hardware and technological scheme of CO2-extract manufacture

Figure 1. Hardware and technological scheme of CO2-extract manufacture

1 – extractors; 2 – the condenser; 3 – the evaporator; 4 – the compilator;

5 – the safety valve; 6 – the frame; 7 – the gauge; 8 – the filter

Raw materials intended for processing are loaded in mesh tapes and placed in a subcritical extractor 1. Liquid CO2 is supplied from the condenser 2 through the valve B3. At first CO2 impregnates raw materials, the formed miscella is supplied into the evaporator 3 then through the valve B6. Then the hot water is supplied to the steam jacket of the evaporator 3, wherein the solvent abruptly boils in the miscella and then is supplied to the condenser 2 through the valve B1. CO2-extract is released from the miscella through the valve B8, and then is supplied to the compilator 4.

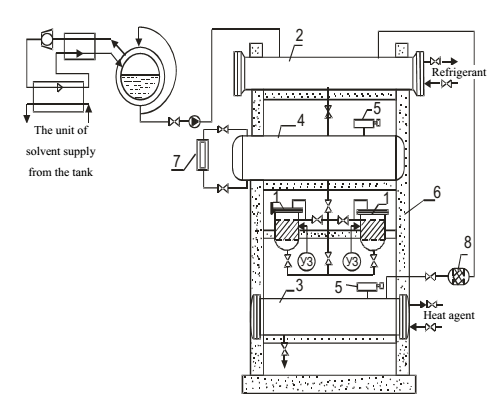

The combined scheme of sub – and supercritical extraction of valuable components from vegetative raw materials is represented in figure 2.

Figure 2. The combined scheme of sub- and supercritical extraction

of valuable components from vegetative raw materials

1 – the subcritical extractor; 2 – thecondenser; 3 – the supercritical extractor;

4 – the separator; 5 – the evaporator; 6 – thecollector

The supercritical extraction process is organized as follows. Initially the evaporator 5 is filled with liquefied CO2. Pressurized fluid carbon dioxide is supplied to the supercritical extractor 3 through a layer of vegetative raw materials (in the tape). Proceeding to a cooled gas separator 4 the miscella is separated into a gas phase and a CO2-extract which is transmitted to a collector 6.

The exploitation experience of the extraction equipment and the stable indicators of the quality of manufactured product essentially confirm the high efficiency of new elements of the processing equipment. Some investigation results (conditions of processing regimes) allow to conclude that the yield of extractive substances essentially depends on the raw material processing.The largest economic effect is achieved if supercritical carbon dioxide for the extraction of valuable components from the vegetative raw materials is used.

Under the leadership and with the participation of the author chemical and biological investigations of more than 100 kinds of domestic and imported fruit and vegetables were conducted. Additionaly the authors investigated spicy-flavor, aromatic, oil seed and other raw materials including unconventional raw materials and the previously unused wastes of food raw materials. The authors identified suitability and perspective of usage of such species of raw materials which are the most expedient for use of CO2-technologies.

The scientific bases of new food and refrigeration equipment were developed (selective extraction, flow-jet processing in a gas-dynamic cooler etc.).

In addition, we proposed and tested a new method of processing of meat raw materials with compressed carbon dioxide under the pressure of 3…5 MPa. This method allows to reduce the pH index of meat up to 1.5…2.0 units. The collagen swelling is increased sharply when the pH index is shifted to the acidic or alkaline level from the isoelectric point. CO2-processing of meat allows to saturate all the volume of meat. The interaction between CO2 and water leads to the formation of weak carbonic acid which being unstable is dissociated irreversibly and shifts pH to the acid area.

The collagen structure is loosened under the action of carbonic acid. That is caused by excess of positive charge in collagen whose fibrils are expanded in polar areas because of the repulsion of similar charged groups. The water passes to the extended area and the swelling takes place. It also leads to the increase of the tenderness of meat that was confirmed during investigation. The swollen loosenes collagen becomes more accessible for digestive enzymes that is very important for present food scientific doctrine about the necessity of including the digestible collagen in diets of adults and children.

The regularities of substanc crystallization in complex systems “CO2- component” were determined which allowed to develop the technology of tartar removal from grape juice and wine.

The conditions of formation of cooled hydroaerosols and of manufacture of “dry snow” in the system “CO2-water” were determined. Their usage allows to cool fruits and vegetables after the harvest and increases the storage period 1.5…2 times without decrease of their quality.

The ways of intensification of vegetative raw material drying period in 1.2…1.5 times were determined. That is achieved with the help of raw material processing by liquified and gaseous CO2 for the removal of the cuticular lipid layer from the surface of leaves and fruits, for foam-forming of porous structure of fruit purees without adition of surface active substances.

We determined the prospective usage of the homogenization method for reprocessing of fruit and vegetable purees and other pastes during CO2-processing with the sequential pressure changes from 4.3 MPa to 0.3 MPa. Also we investigated the effect of CO2-processing on quality indicator set of homogenized products, grape juice and extracts from more than 50 kinds of raw materials including cuticular waxes.

The technology of vegetative raw material reprocessing was developed. The technology of food byproduct manufacture for water-soluble biological active additives (on the basis of which were created more than 40 recipes of different kinds of cosmetic products protected by patents of the Russian Federation) was developed.

We proved the possibility of efficiency control of extraction of valuable components from vegetative raw materials by the targeted distraction of the cellular structure of the material (“explosive cell technology”) as well as the sharp reduction (10…100 times) of bacterial contamination of raw materials which are recycled by CO2-technologies.

The created technologies have no analogues abroad. Technological processes and the equipment for CO2-processing of animal and vegetative raw materials are used in numerous enterprises in the Russian Federation and countries of CIS (Commonwealth of Independent States). They allowed:

- to implement CO2-extraction of vegetable, spicy-aromatic and medicinal raw materials in regimes of subcritical and supercritical pressure of carbon dioxide;

- to process raw materials with the purpose to reduce the microbial contamination, detartration, ultrathin grinding of fruits and vegetables, to remove the cuticular wax layer from the surface of fruits and leaves, to saturate water etc.;

- to homogenize large-grinded raw materials by the gas-liquid method and to obtain products suitable for usage in therapeutic, preventive nutrition and in child’s food;

- to provide cooling technology of products (poultry, cooked sausages, meat, vegetables, fruits, herbs, etc.) with ice water and granulated “dry snow”;

- to develop manufacture of perfume and cosmetic products of consumer and special usage based on received CO2-extracts, their compositions and biologically active substances;

- to master manufacture of drinks from whey, fruit kvass and other liquid products based on obtained CO2-extracts;

- to develop the manufacture of meat, fish and fish and vegetative canned products with the usage of obtained CO2-extracts;

The modern theoretical and analytical base for the further development of new industrial direction in food industry was developed. This base includes:

- combined methods of analysis of thermodynamic efficiency of the process (selective extraction, flow-jet crystallization) in “Energy-Economy-Ecology” system;

- selection methodology and definition of succuession of engineering design development for evaluation of interrelated regime and technological characteristics of the original equipment for CO2-technologies;

- generalized approaches to the usage of scientific investigated results and pilot production tests, physical, chemical and biological analyzes of products obtained with the usage of CO2-technologies for synthesizing new perspective technologies applied to the new assortment of raw materials.

Сonclusion

The extensive and diversfied researches for many years, engineering design of pilot production developments in the area of carbon dioxide usage as a technological agent were performed under the supervision of Kasyanov G.I. The investigation allowed to achieve the most important technological results. Using the methods of the systematic analysis the concept of a new scientific field (single application system of carbon dioxide) in food industry for creation of fundamentally new high-tech CO2-processing of raw materials of different origin was formulated.

Regularities of interaction, functioning and technological process development which all are based on interaction of food with carbon dioxide in stable or changing phase conditions were determined. All this allowed to develop the scientific basis of engineering solutions in the field of engineering and CO2-processing technology.

References

- Kasyanov G.I. Technological bases of CO2-processingof vegetative raw materials // Moscow, Russian Agricultural Academy, 1994, 132 p.

- Silinskaya S.M., Kasyanov G.I. Technology for processing of keratin vegetative raw materials by gas-liquid extraction methods //Krasnodar, KSRISRAP 2005, 147 p.

- Kasyanov G.I., Derevenko V.V., Sobolev E.M. Achievements of integrated scientific school “Electrophysical, gas-liquid and nanobiotechnology methods of vegetative and animal raw material processing” //Izvestia vuzov. Pishevaya tekhnologia , № 2-3, 2012, pp. 113-117.

- Kasyanov G.I., Gerasimova N.Y. Processing of vegetative raw materials by methods of sub- and supercritical CO2-extraction // Cannery production, №1, 2012, pp. 20-23.

- Kasyanov G.I. Gas-liquid and electromagnetic methods of processing animal raw materials // Izvestia vuzov. Pishevaya tekhnologia, №1, 2012, pp. 37-39.

- Kasyanov G.I., Bokovikova T.N., Tarasov V.E. Carbon dioxide: manufacture and usage // Krasnodar, EKOINVEST, 2010, 171 p.

- Kasyanov G.I. CO2-extracts. Manufacture and usage (under reduction of prof. Shcherbakov V.G.) // Krasnodar, EKOINVEST, 2010, 176 p.

- Kasyanov G.I., Korobitsin V.S.The extraction of valuable components from vegetative raw materials by methods of supercriticalCO2-extraction // Krasnodar, KubSTU, House-South Editor, 2010, 132 p.

- Staseva O.N., Latin N.N., Kasyanov G.I. CO2-extractsof Caravan Company - the new class of natural food supplements // Krasnodar, KSRISRAP, 2011, 324p.

- Russian Federation Patent number 2058349. WPC: C 09 B 61/00. The method of manufacture of dye from onion peel / O.I.Kvasenkov, G.I. Kasyanov.

- Russian Federation Patent number 2166260. WPC: A 23 L 1/221. The method of extract obtained from subtropical and aromaticvegetative raw materials / G.I. Kasyanov, I.E. Kizim.

- Franco E.P., Kasyanov G.I.The CO2-extractionof melon seeds // Izvestia vuzov. Pishevaya tekhnologia , №2-3, 2010, pp. 121-122.